- Understanding the Role of Ratilroad Track Construction Compary

- Challenges Faced by Ratilroad Track Construction Compary

- Best Practices for Efficient Ratilroad Track Construction Compary

- Impact of Technology on Ratilroad Track Construction Compary

- Frequently Asked Questions About Ratilroad Track Construction Compary

Understanding the Role of Ratilroad Track Construction Compary

Overview of Rail Track Construction

Rail track construction is a critical component of transportation infrastructure, enabling the movement of goods and passengers across vast distances with efficiency and speed. A well-constructed rail system comprises various elements including tracks, ties, subgrade, and ballast, all designed to support the weight and speed of trains while ensuring safety and reliability. The process of rail track construction involves meticulous planning, careful execution, and ongoing maintenance to adapt to changing technologies and environmental impacts. Within this domain, companies like Ratilroad Track Construction Compary play a pivotal role, utilizing industry standards and innovative practices to deliver high-quality results.

Importance of Quality in Rail Infrastructure

The quality of rail infrastructure is paramount to the safe and efficient operation of transportation networks. Poorly constructed rail systems can lead to derailments, accidents, and significant delays, all of which impose high costs on both companies and consumers. High-quality materials and construction practices ensure that tracks can withstand weather conditions, heavy loads, and wear over time. Additionally, quality assurance processes contribute to the longevity of rail assets, minimizing the need for premature replacements or repairs and enhancing overall reliability.

Key Players in Ratilroad Track Construction Compary

The ecosystem of railroad track construction is populated by various key players, each contributing to the successful completion of projects. These include civil engineers, construction workers, project managers, and quality inspectors, all of whom collaborate to design, build, and maintain rail infrastructure. Additionally, suppliers and manufacturers providing rails, ties, and specialized equipment are integral to ensuring that construction projects are equipped with the best tools and resources available. Understanding the roles of these players helps streamline processes and improve communication across all project stages.

Challenges Faced by Ratilroad Track Construction Compary

Environmental Considerations

As concerns about climate change and environmental degradation grow, the railroad industry faces increasing scrutiny regarding its impact on natural ecosystems. Companies engaged in railroad track construction must navigate regulations that govern land use, species protection, and redress for ecological footprints. Sustainable practices, including the use of recycled materials, minimizing habitat disruption, and implementing noise reduction technologies, are becoming essential components of modern construction strategies to address environmental concerns.

Budget and Resource Management

Effective budget and resource management are vital for the success of any railroad track construction project. Cost overruns and resource shortages can derail timelines and compromise project quality. Companies must engage in thorough planning and forecasting, including economic assessments, to allocate funds efficiently and prevent mismanagement. Utilizing project management tools and methodologies can assist in tracking expenditures and timelines, ensuring that projects remain on budget and within scope.

Technological Advancements

The railroad industry is witnessing rapid technological advancements that transform construction practices. While such innovations can enhance efficiency and safety, they often require significant investments and retraining of personnel. Companies may encounter challenges in integrating new tools such as automated track laying machines, GPS-guided equipment, and drone technology for surveying and monitoring progress. Addressing these challenges involves strategic planning and investment in workforce training to fully leverage emerging technologies.

Best Practices for Efficient Ratilroad Track Construction Compary

Planning and Project Management

Robust planning and project management are critical for the timely completion of railroad track construction projects. Effective planning involves setting clear objectives, identifying potential risks, and establishing communication protocols among stakeholders. Utilizing project management software can facilitate task scheduling, resource allocation, and progress tracking. Additionally, adopting Agile methodologies allows teams to adapt quickly to changes, ensuring flexibility in addressing obstacles as they arise.

Safety Standards and Regulations

Safety is a non-negotiable aspect of railroad track construction. Following industry safety standards and regulations minimizes risks to workers and the general public. Companies must conduct regular safety training, hold safety meetings, and implement comprehensive safety plans before commencing work. Compliance with local, state, and federal regulations ensures a safe work environment and protects the integrity of the construction process.

Innovative Techniques in Track Construction

Adopting innovative techniques in track construction can significantly improve efficiency and quality. Techniques such as continuous welded rail (CWR) installation, mechanized tamping, and advanced rail fastening systems enhance alignment, reduce maintenance costs, and improve ride quality. Emphasizing research and development can lead to discovering new methods that further streamline operations while adhering to environmental and safety standards.

Impact of Technology on Ratilroad Track Construction Compary

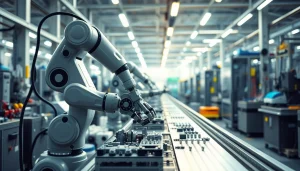

Automation and Robotics in Construction

Automation and robotics are reshaping the landscape of railroad track construction. Automated machinery can assist in tasks such as rail laying and ballast distribution, significantly decreasing the time required for construction. These technologies not only improve efficiency but also reduce human error, leading to higher-quality outcomes. However, implementing these solutions involves upfront costs and necessitates training for workers to operate and maintain such advanced equipment.

Data Analytics for Predictive Maintenance

Data analytics plays a crucial role in the predictive maintenance of railway infrastructure. By collecting and analyzing data on wear patterns and usage, companies can anticipate potential issues before they escalate into serious problems. This proactive approach helps extend the lifespan of rail assets and ensure the safety and reliability of rail services. Investing in data analysis technology can dramatically enhance maintenance scheduling, reducing downtime and overall costs.

Future Trends in Track Construction Technology

The future of track construction technology is promising, with trends pointing towards increased automation, smart materials, and enhanced sustainability. Innovations such as 3D printing for rail components and smart sensors embedded in tracks to monitor conditions will likely emerge. As technology continues to evolve, companies that embrace these trends will maintain a competitive edge, remaining responsive to market demands and environmental requirements.

Frequently Asked Questions About Ratilroad Track Construction Compary

What is involved in railroad track construction?

Railroad track construction involves designing and building railway tracks and associated infrastructure, including ties, ballast, and subgrades. It requires careful planning, execution, and compliance with safety standards.

How does technology improve construction processes?

Technology enhances construction processes through automation, advanced data analytics, and innovative construction practices, leading to greater efficiency, improved safety, and reduced costs.

What challenges do companies face in this industry?

Companies face challenges such as environmental regulations, budget and resource management, and integrating new technologies into traditional construction practices.

Why are safety standards important?

Safety standards are crucial in preventing accidents and ensuring the well-being of workers and the public. Compliance demonstrates a commitment to maintaining a safe construction environment.

What future trends should we expect?

Future trends include increased automation, the use of smart materials, and data-driven approaches for predictive maintenance, all contributing to more efficient and sustainable rail construction practices.