The Evolution of Plastic Injection Molding Machines

The world of manufacturing is continuously evolving, but few technologies have shaped the industry as profoundly as plastic injection molding machines. These machines play a pivotal role in producing a vast range of consumer and industrial products, demonstrating efficiency that is hard to match. In recent years, advancements in technology have not only enhanced the performance capabilities of these machines but have also expanded their applicability across various sectors. As we approach 2025, understanding the evolution of plastic injection molding machines becomes crucial for manufacturers aiming to stay competitive. For those seeking high-quality solutions, exploring options like plastic injection molding machines can provide comprehensive insights into the latest offerings and technologies available.

Overview of Injection Molding Technology

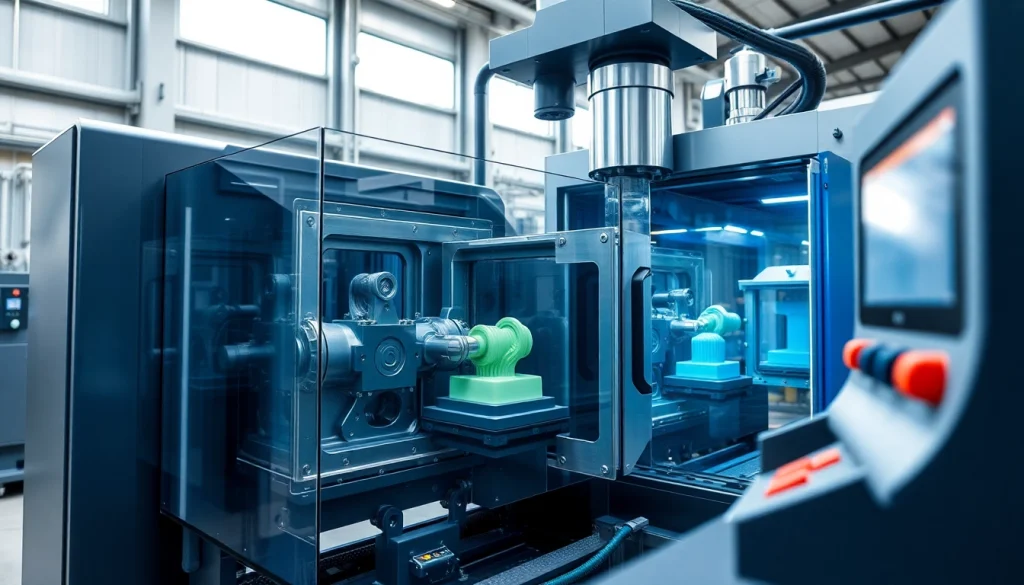

Injection molding is a manufacturing process used to produce identical plastic parts by injecting molten material into a mold. The process involves melting plastic pellets and forcing the liquid into a precisely shaped cavity. As the plastic cools and solidifies, it takes the shape of the mold. This technique is celebrated for its efficiency, allowing for high-volume production with minimal waste.

The technology behind plastic injection molding machines has advanced significantly, incorporating automation, improved software for precision control, and energy-efficient systems. As a result, manufacturers can produce intricate components that meet stringent quality standards at lower costs and in shorter time frames.

Significant Advancements in 2025

As we look ahead to 2025, several significant advancements are expected to reshape the landscape of plastic injection molding. Key trends include enhanced automation through robotics, which will streamline operations and reduce labor costs, as well as the integration of IoT devices that will allow for real-time monitoring and predictive maintenance.

Additionally, developments in material science will enable manufacturers to work with a wider variety of sustainable and recycled materials, aligning with growing environmental regulations and consumer demand for eco-friendly products. These advancements will not only aid in reducing the overall carbon footprint of production but will also enhance the versatility of injection molding machines.

Comparative Analysis of Electric vs. Hydraulic Machines

When choosing a plastic injection molding machine, manufacturers often face the decision between electric and hydraulic models. Electric machines are celebrated for their precision and energy efficiency, making them ideal for applications requiring tight tolerances. In contrast, hydraulic machines are typically better suited for larger production runs and heavier molds, offering more clamping force and faster cycle times.

As technology progresses, however, the gap between these two types continues to narrow, with hybrid models emerging that combine the best features of both. This enables manufacturers to achieve optimal performance tailored to their specific production needs.

Key Features to Consider in 2025

Understanding the essential features of plastic injection molding machines is crucial for manufacturers as they prepare for the future. The right machine can significantly enhance production efficiency and product quality, while poor choices can lead to wasted resources and increased downtime.

Energy Efficiency in Plastic Injection Molding Machines

Energy efficiency is a critical factor in selecting a plastic injection molding machine in 2025. Electric models, in particular, are known for their lower energy consumption compared to hydraulic counterparts. The integration of energy-saving technologies, such as servo-driven drives and advanced temperature control systems, can further enhance efficiency, making it essential for manufacturers to consider these options.

Precision Control Systems for Optimal Performance

In an era where precision is paramount, the ability to control every aspect of the injection molding process is crucial. Look for machines that incorporate advanced control systems with real-time feedback mechanisms. These systems allow for meticulous monitoring and adjustments, contributing to higher product quality and consistency in output.

Modular Design Advantages for Versatile Applications

Modular designs in plastic injection molding machines offer significant advantages, allowing manufacturers to adapt machines to various production needs. This flexibility ensures that businesses can respond to changing market demands without needing entirely new equipment. Modular units can be customized for specific applications, enhancing productivity and efficiency in the long run.

Choosing the Right Plastic Injection Molding Machine

Selecting the appropriate plastic injection molding machine requires careful consideration of multiple factors, including production requirements, cost-effectiveness, and vendor reliability.

Assessing Production Requirements and Capacities

Manufacturers should begin by evaluating their production goals, including the type of products, volume, and specific tolerances required. Understanding these factors will help narrow down the options available and identify machines capable of meeting the demands of various applications.

Evaluating Cost-effectiveness and ROI

While the initial cost of a plastic injection molding machine is vital, the overall return on investment (ROI) should also be a key consideration. Assess the operational costs, including energy consumption, downtime, and maintenance requirements, to determine which machine will deliver the best long-term value. In many cases, choosing a slightly more expensive machine with advanced features can lead to significant savings over its lifetime.

Identifying Trusted Manufacturers and Suppliers

Partnering with reputable manufacturers and suppliers is crucial for ensuring quality and reliability. Look for companies with a proven track record in the industry that provide comprehensive support, from installation to after-sales services. Reading reviews and case studies can also provide insights into how well a supplier’s machines perform in real-world applications.

Common Challenges in Injection Molding

Despite its advantages, the injection molding process is not without its challenges. Recognizing these potential obstacles can help manufacturers develop strategies to mitigate risks and optimize production.

Addressing Quality Control Issues

Quality control is an ongoing concern in the injection molding industry. Common issues such as inconsistent product dimensions, surface defects, and material inconsistencies can lead to costly rework and waste. Implementing robust quality management systems and utilizing advanced monitoring technologies can help manufacturers identify problems early, ensuring that high standards are maintained throughout the production process.

Common Misconceptions About Plastic Injection Molding

Many misconceptions surround plastic injection molding that can hinder manufacturers’ decision-making processes. For instance, some believe that the technology is only suitable for large-scale operations, but recent advancements have made it feasible for smaller manufacturers as well. Educating stakeholders about the capabilities and flexibility of modern plastic injection molding machines can help dispel these myths and encourage more efficient production practices.

Strategies for Overcoming Operational Obstacles

Common operational obstacles such as machine downtime, maintenance issues, and workforce challenges can significantly impact productivity. Investing in training programs for operators, establishing routine maintenance schedules, and leveraging predictive analytics can help mitigate these challenges, ensuring that production runs smoothly and efficiently.

Future Trends in Plastic Injection Molding

The future of plastic injection molding is poised for exciting transformations. As manufacturers adopt more innovative practices, several trends are expected to influence the industry significantly.

Impact of Automation and Robotics in 2025

The integration of automation and robotics into the injection molding process is set to increase significantly by 2025. These technologies will streamline operations, enhance consistency, and reduce labor costs, making it easier for manufacturers to meet growing demands while maintaining quality.

The Role of Sustainable Practices in Manufacturing

With increasing emphasis on sustainability, the injection molding industry is also evolving to incorporate eco-friendly practices. The use of bio-based materials, recycling initiatives, and energy-efficient machines will become standard practices. Manufacturers who adapt to these trends will not only comply with regulations but also appeal to environmentally conscious consumers.

Predictions for Industry Innovations and Developments

As manufacturers look towards the future, continuous innovation will be key. We can expect advances in material technology, enabling the use of higher-performance plastics and composites, as well as improvements in machine design that enhance efficiency and reduce waste.

Overall, the landscape of plastic injection molding machines will be defined by a commitment to precision, efficiency, and sustainability as we move into 2025 and beyond.