Understanding Diecasting in Malaysia

Diecasting is a critical manufacturing process that plays an essential role in the production of precision metal components across various industries. In Malaysia, the diecasting sector has been experiencing significant growth, fueled by advancements in technology and a rising demand for high-quality metal parts. From automotive to electronics, diecasting is integral to enhancing production efficiency and product quality. When exploring options, diecasting malaysia stands out as a key player in this burgeoning industry.

The Basics of Diecasting Technology

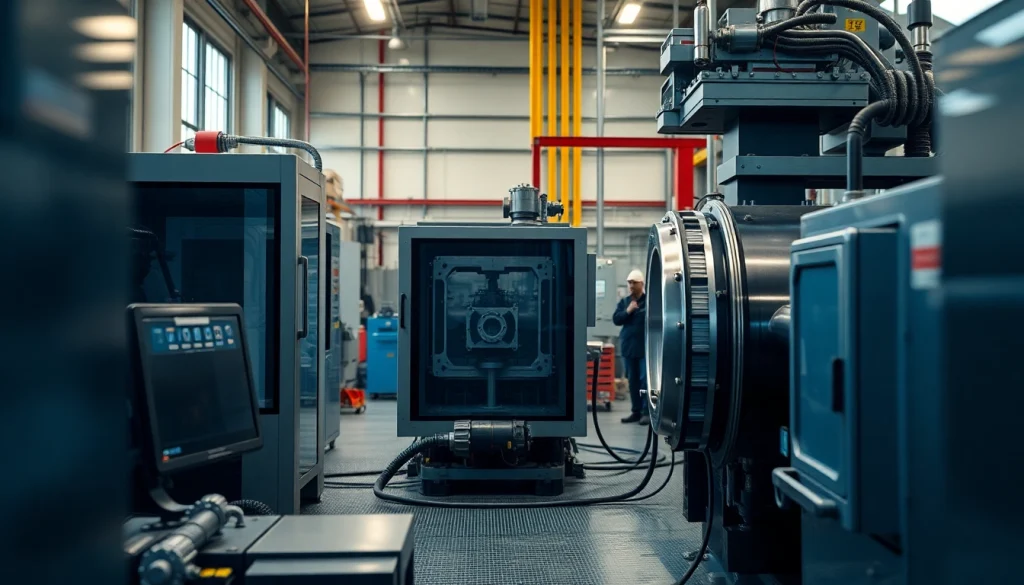

At its core, diecasting is a manufacturing process that involves forcing molten metal into a mold cavity at high pressure. This technique offers several advantages, including the ability to produce complex shapes with high dimensional accuracy. The two predominant methods of diecasting employed are:

- High-Pressure Diecasting: Utilized predominantly for non-ferrous metals like aluminum and zinc, high-pressure diecasting involves injecting molten metal into a steel mold under extremely high pressure. This process can achieve high production rates and consistent quality, making it ideal for components that require intricate designs.

- Low-Pressure Diecasting: This method involves using lower pressure to fill the mold, allowing for better control over the metal’s flow. While it may be slower than high-pressure diecasting, it can produce larger parts and is often used in industries where weight and strength are critical.

The Importance of Diecasting in Various Industries

Diecasting plays a pivotal role in various sectors, significantly contributing to their efficiency and innovation. Key industries benefiting from diecasting include:

- Automotive: Diecasting components such as engine blocks, transmission cases, and structural parts help manufacturers reduce weight while improving durability and performance.

- Electronics: The production of casings, housings, and connectors through diecasting allows for intricate designs with precise specifications, essential for modern electronic devices.

- Aerospace: Diecast parts are crucial in aerospace applications, where weight reduction and strength are paramount to flight safety and fuel efficiency.

- Consumer Goods: Many household items, from kitchen appliances to tools, utilize diecasting technology to achieve both aesthetic appeal and functional durability.

Advantages of Choosing Diecasting

Selecting diecasting as a manufacturing process offers numerous benefits that can significantly enhance production capabilities and product quality.

Cost-Effectiveness for Large Production Runs

One of the most compelling advantages of diecasting is its cost-effectiveness, especially for large volume production runs. The initial setup costs for dies are relatively high, but the benefits become apparent as production scales:

- Reduced labor costs due to automation and streamlined processes.

- Minimized material waste, which lowers the overall production cost.

- High throughput rates, enabling manufacturers to meet large-scale demands quickly.

Precision and Quality of Metal Components

Diecasting is renowned for its ability to produce parts with exceptional dimensional accuracy and surface finish. This precision ensures that components fit together correctly, reducing the need for additional machining or finishing processes. The consistent quality of diecast parts can help manufacturers:

- Enhance product reliability and performance.

- Reduce the likelihood of defects.

- Streamline assembly processes, leading to faster time-to-market.

Sustainability and Material Efficiency in Diecasting

With growing concerns about environmental impact, diecasting processes are evolving to become more sustainable. Techniques such as recycling scrap materials and utilizing advanced alloys contribute to:

- Lower carbon footprints due to reduced energy consumption.

- Enhanced material efficiency through the use of lighter metals that require less energy to manufacture.

- Promoting circular economy principles by reusing materials and reducing waste.

Common Challenges in the Diecasting Process

While diecasting presents numerous advantages, it also faces distinct challenges that manufacturers need to address effectively to maintain quality and efficiency.

Addressing Defects in Diecasting

Common defects such as porosity, incomplete filling, and surface imperfections can arise during the diecasting process. To mitigate these issues, manufacturers should:

- Conduct regular maintenance of dies to ensure optimal performance.

- Implement advanced simulation software to predict and prevent defects before production.

- Employ stringent quality control measures throughout the manufacturing process.

Managing Production Costs Effectively

Controlling production costs without compromising on quality is a persistent challenge in diecasting. Companies must balance the need for high-quality materials and advanced technology with budget constraints. Strategies include:

- Investing in efficient machinery to reduce operational costs.

- Negotiating bulk raw material purchasing agreements to lower material costs.

- Exploring automation options to minimize labor costs.

Navigating Supply Chain Issues in Malaysia

Malaysia’s diecasting industry, like many others, faces supply chain challenges exacerbated by global events. Companies must adopt strategies such as:

- Diversifying suppliers to mitigate risks associated with supply chain disruptions.

- Implementing just-in-time inventory systems to reduce warehousing costs.

- Leveraging local sourcing to enhance supply chain resilience.

Innovative Practices in Diecasting Manufacturing

The diecasting industry is continually evolving, driven by innovation and the adoption of new technologies that enhance efficiency and product quality.

Embracing Automation and IoT Technologies

Integrating automation and IoT (Internet of Things) technologies into diecasting processes can significantly improve production efficiency. Benefits include:

- Real-time monitoring of production lines to identify issues promptly.

- Enhanced process optimization through data analytics.

- Reduced labor dependency by automating repetitive tasks.

Implementing Quality Control Measures

To maintain high standards, it’s vital to implement rigorous quality control measures. This can be achieved through:

- Incorporating automated inspection systems using AI technologies.

- Conducting regular training programs for staff on quality management practices.

- Utilizing advanced materials and coatings to enhance product durability.

Future-Focused Material Selection Trends

As diecasting technologies advance, material selection is becoming increasingly important. Manufacturers are focusing on:

- High-strength alloys that offer better performance and longevity.

- Lightweight materials to enhance energy efficiency in end products.

- Biodegradable materials in certain applications to address environmental concerns.

Looking Ahead: Future Trends in Diecasting Malaysia

The diecasting industry in Malaysia is poised for growth and transformation as it adapts to evolving market demands and technological advancements.

Predicted Growth of the Diecasting Sector by 2025

Recent market analyses indicate that the diecasting sector in Malaysia is expected to witness steady growth, driven by burgeoning industries and increased investments in manufacturing capabilities. Factors contributing to this growth include:

- Rising demand for lightweight components in various industries, particularly automotive and aerospace.

- Government initiatives promoting local manufacturing and technology adoption.

- Increased foreign investments in Malaysia’s manufacturing sector.

Emerging Technologies in Diecasting

As the industry evolves, emerging technologies such as additive manufacturing and advanced robotics are likely to shape diecasting practices. These innovations can lead to:

- Enhanced design flexibility, allowing for the production of more complex geometries.

- Reduced lead times for prototyping and production.

- Improved quality and performance of diecast components.

Shifts in Consumer Demands and Sustainability Practices

Changing consumer preferences are pushing manufacturers to adopt more sustainable practices. Companies can respond to these trends by:

- Implementing eco-friendly production processes.

- Offering products made from recycled materials.

- Engaging in corporate social responsibility initiatives to promote sustainability.